Full-scale aerosol challenge tests of protective garments for the U.S. military, manufacturers, and users

Military service members, first responders, and those whose jobs require them to work with hazardous materials rely on protective fabrics and garments to shield them from exposure to dangerous chemicals and bioaerosols.

We offer unparalleled expertise and experience in aerosol challenge testing to ensure these fabrics and garments will perform under the full range of conditions. We work with manufacturers and users of these garments to develop and conduct independent third-party tests that deliver comprehensive, reliable results our clients can trust.

A leading authority in this field, we developed the aerosol systems and swatch test methodologies now specified for aerosol challenge tests by the U.S. military and the National Fire Protection Association (NFPA).

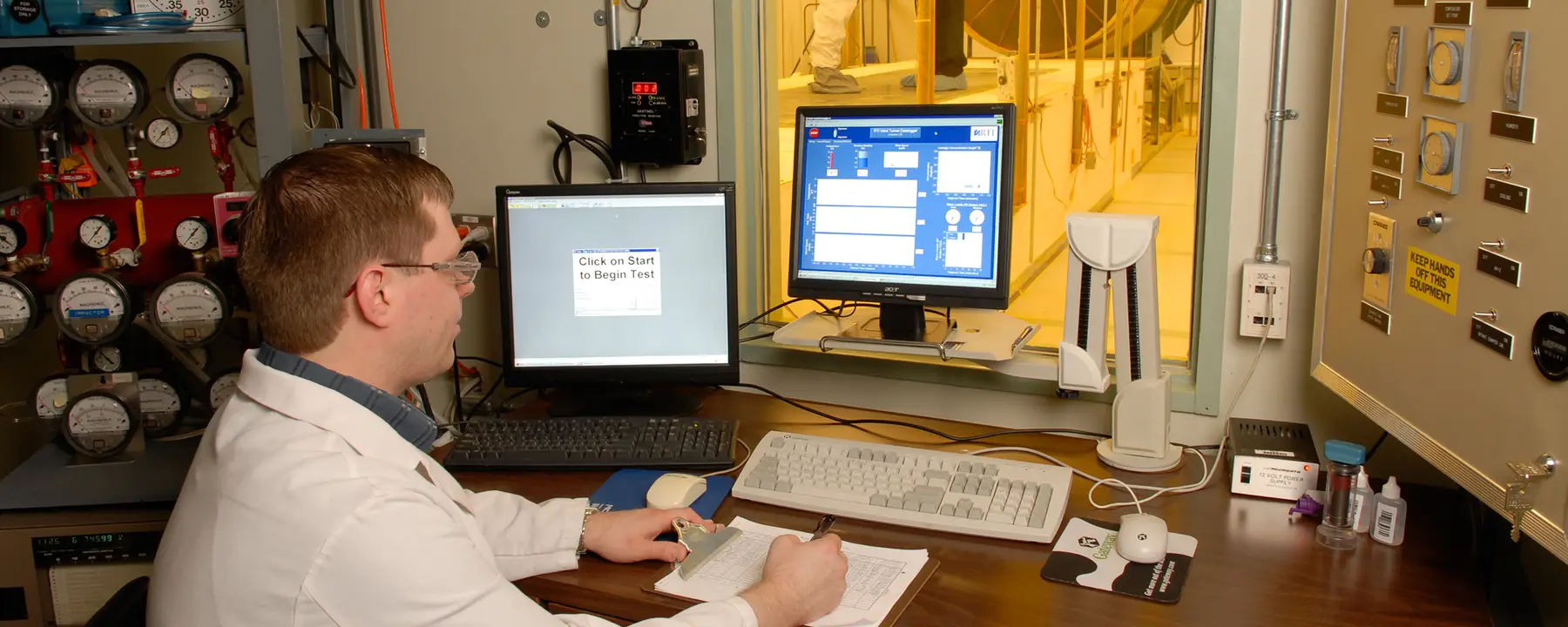

Wind Tunnel for Aerosol Testing of Protective Garments

We conduct human-subject testing of chemical protective ensembles under controlled environmental conditions. Our facility is equipped to allow full control of temperature, relative humidity, wind speed, and aerosol conditions to provide a wide range of challenge conditions that suit our clients’ needs. Our testing services include direct quantification of aerosol deposition on skin and clothing, as well as Test Operations Procedure (TOP) 10-2-022 and National Fire Protection Association (NFPA) 1994 Class 4 particle inward leakage tests.

Our lab houses a dedicated wind tunnel aerosol exposure facility for full-scale aerosol challenge tests of military and first responder protective garments. Key features of this open-jet recirculating wind tunnel include

- A 7-foot diameter, 40-hp vane-axial fan centrally located in a 28 feet by 50 feet sealed room

- Wind speeds up to 40 mph within a 6-foot diameter test section

- Control room, doffing area, and sampling room

- Separate donning and garment storage areas

- Controlled environmental conditions

- Recirculating, high-efficiency filtration system and an ambient air purging system.

Component-level tests can also be performed such as testing prototype hoods, closures or interfaces in support of an ensemble development effort.

Aerosol Preparation and Generation

In support of garment research and testing, we prepare and analyze solid- and liquid-phase fluorescently tagged challenge aerosols. By using fluorescent tracers, we can accurately measure aerosol deposition on skin and clothing and minimize background interference from ambient aerosol, shed clothing fibers, carbon dust, and other potential contaminants.

Aerosol Swatch Testing

We have a quality-built, dedicated apparatus for measuring the aerosol penetration of fabric swatches over the particle diameter size range from 0.01 – 5 µm. The system features

- A smooth static-free duct constructed of polished steel

- Temperature and humidity controls enabling us to test under a wide range of conditions

- Constant pressure drop and constant face velocity modes

- Scanning mobility particle sizer (SMPS) and a high-resolution optical particle counter (OPC) for measuring concentration of aerosols at a range of particle sizes

- Laminar flow element for measuring flow rate through a test swatch

- Micromanometer for measuring pressure drop

Challenge aerosols are either oil or salt generated with a nebulizer.

- Defense and first responder communities

- Garment manufacturers and designers