Designing innovative solutions to reduce costs and energy demand associated with mitigating CO2 emissions

The cost of technologies to address the CO2 emissions generated by large, stationary point sources needs to be as low as possible to reduce raising the costs of industrial products such as electricity, cement, petrochemicals, and paper. For over a decade, our team has explored CO2 capture and utilization technologies that could positively impact fossil fueled power and industrial sectors.

RTI's Innovative CO2 Capture and Conversion Technologies

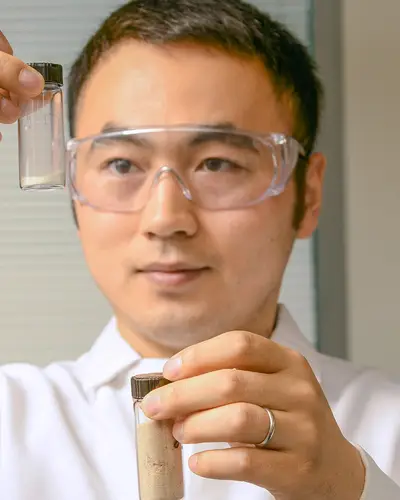

Drawing on our extensive background in materials and process development, we apply approaches based on solvents, solid sorbents, and hybrid technologies for pre-and post-combustion CO2 capture in power generation, cement production, petroleum refining, and other areas. Our bench-scale gas absorption system, located at the RTI Pilot Xcelerator, can evaluate CO2 capture solvents using simulated or real (via RTI’s fuel combustor) flue gas streams. It features an absorber tower, advanced controls, a rotating bed unit, and precise energy monitoring.

We also developed RTI’s non-aqueous solvent (NAS) for CO2 capture, which substantially reduces the specific reboiler duty (SRD) by 40% compared to bench-mark approaches. It can remove over 99% of CO2 emissions from natural gas combustion exhausts. Our NAS technology has gained global attraction with global energy and construction leaders like SLB New Energy and CEMEX.

Removing CO2 from point source emissions is a practical way to use fossil fuels responsibly. The captured CO2 can be sequestered underground where it can aid in enhanced oil recovery or become mineralized over time. It can also be converted into useful products at the surface such as methanol or hydrocarbons. At RTI we use a synfuels unit to convert CO2 to low-carbon-intensity fuels, including jet fuel. We do this at the barrels/day scale to assist technology developers working on innovative technologies to make synthetic fuels and chemicals cost competitive.

Our Suite of Carbon Capture Technologies and Capabilities Includes:

- Non-aqueous solvents

- Solid sorbents

- CO2 conversion and utilization for fuels and chemicals production

- Process design, modeling and technoeconomic analysis

- Scale-up and industrial implementation

- 0.1 ton CO2/day capture unit built on site

- Rotating packed bed absorber

- Stripper and flash regeneration of solvents

- Fuel combustors for testing on real flue gas

Related Projects

Identifying Opportunities in Carbon Capture and Storage Technologies

Read More about Identifying Opportunities in Carbon Capture and Storage Technologies