Pursuing efficiencies in carbon, hydrogen, and separation to meet renewable fuel standards

As energy independence and sustainability become more important, nations around the world are increasingly turning to renewable fuels as a way to meet their goals. In the United States, the 2005 Energy Policy Act set what is known as the Renewable Fuel Standard, requiring transportation fuels to contain a minimum volume of renewable fuels—a volume that increases each year and will reach 36 billion gallons of renewables by 2022.

To take full advantage of the potential of advanced biofuels to meet this demanding standard, fundamental research and development is needed in biomass liquefaction and bio-oil processing techniques for the production of hydrocarbon biofuels.

Producing a High-Value Liquid Intermediate and Boosting Carbon Recover

Our chemical engineers are developing an improved process with a new class of catalysts for in situ catalytic biomass pyrolysis to maximize the biomass carbon and energy recovery in a liquid intermediate that can be upgraded into advanced biofuel. This bio-crude intermediate has a low oxygen content, is rich in hydrocarbons, and is thermally stable.

In addition to developing these novel catalysts, we are working to improve the carbon efficiency of the integrated process by converting the carbon in the aqueous streams to methane for hydrogen production, recovering oxygenated hydrocarbons for hydroprocessing, or upgrading aqueous-phase carbon to value-added by-products.

Ultimately, we aim to demonstrate production of bio-crude with less than 10 weight percent oxygen, recovering at least 30 percent of the carbon input from biomass and recovering 20 percent of the aqueous phase carbon as methane via an anaerobic membrane bioreactor.

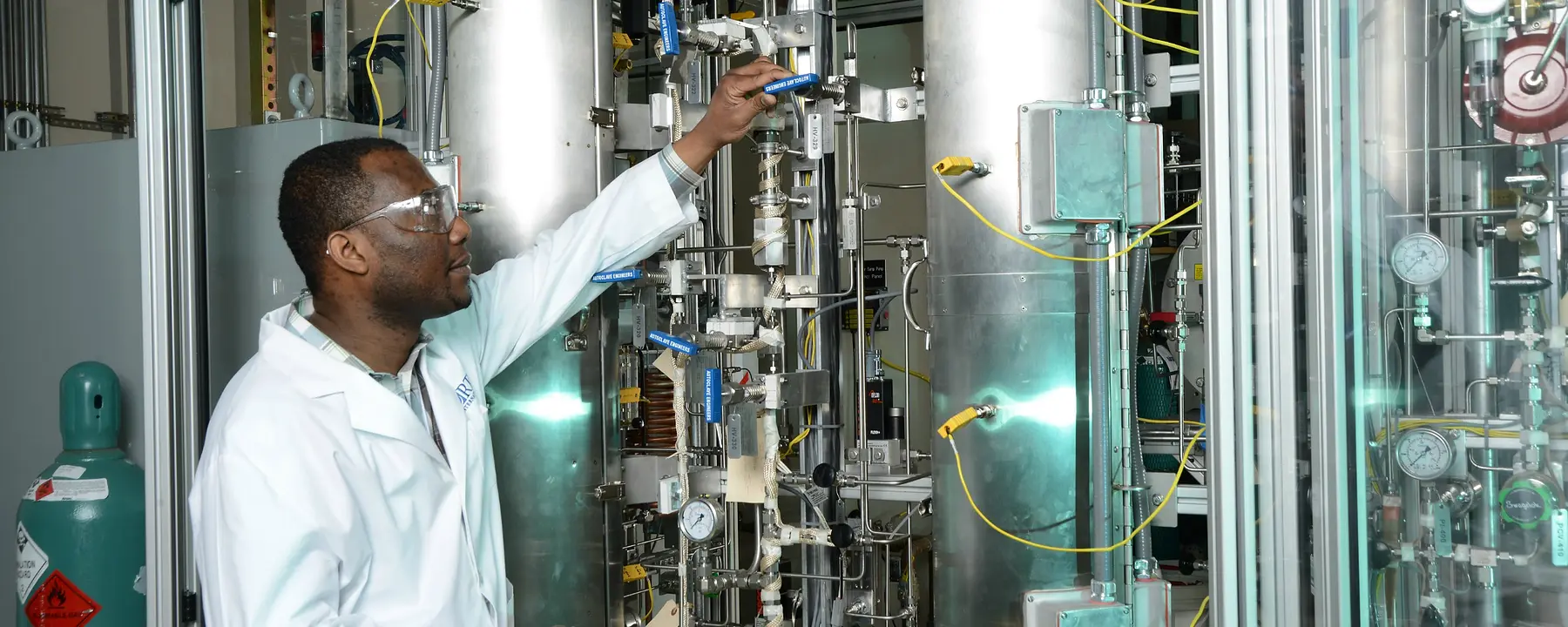

Advanced Research Infrastructure for Bench Scale R&D

Process engineering R&D takes place in our sophisticated Energy Technology Development Facility (EDTF), designed for demonstration of process technologies at the critical transition from bench to pilot scale.

We are conducting detailed studies of pyrolysis reactions, using a micropyrolyzer to rapidly screen catalyst/biomass combinations at a range of temperatures. Our micropyrolyzer uses samples smaller than 1 mg and has an efficient testing time of about half an hour, with flexible temperature ramping and rapid switching of catalyst reaction tubes.

The facility has automated fixed-bed microreactors to study catalytic reaction pathways and fluidized-bed reactor systems to optimize process conditions.

Speeding the Application of Advanced Biofuels to Comply with Renewable Fuel Standards

If successful, our improved pyrolysis process could reduce the conversion costs of biomass to hydrocarbon transportation fuels. By pursuing R&D in thermochemical conversion, we aim to develop commercially viable technologies for converting biomass into energy-dense, fungible, finished liquid fuels, such as renewable gasoline, jet, and diesel. Ultimately, our process could shorten the time required to achieve the Renewable Fuel Standard.

- U.S. Department of Energy (DOE)

- Haldor Topsoe A/S (HTAS)

- Veolia Water Technologies

- Inc.